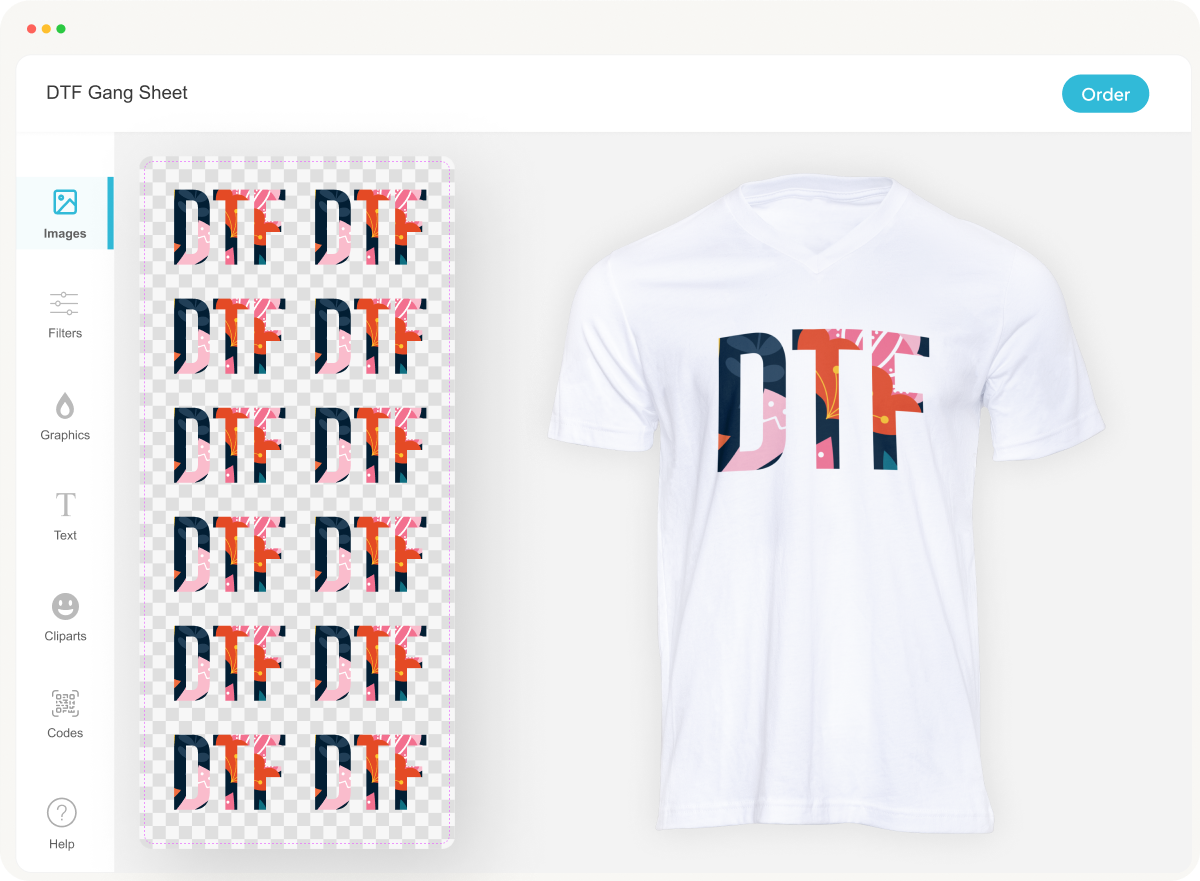

The DTF Gangsheet Builder Print is an innovative solution designed for anyone looking to enhance their custom printing experience through Direct-to-Film (DTF) technology. Whether you’re a beginner eager to learn or a seasoned pro refining your skills, this tool serves as your gateway to creating stunning DTF prints with ease. In our comprehensive DTF printing tutorial, you will discover how to optimize your designs for gangsheet printing, ensuring that every print not only looks great but is also efficient and cost-effective. We will guide you step-by-step, making sure you have the knowledge to master how to DTF print like a professional. Prepare to unleash your creativity and produce high-quality prints that can transform any fabric into a canvas of artistic expression.

When discussing the DTF Gangsheet Builder Print, it’s essential to understand its role in the world of fabric printing. This process, often simply referred to as Direct-to-Film printing, utilizes a specialized film to transfer designs onto various textiles. As you explore this beginner’s guide to DTF, you will learn about the intricacies of gangsheet production, optimizing material use and enhancing your printing output. The method’s efficiency not only streamlines the creation of multiple designs but also ensures that artistic visions come to life vibrantly on fabric. Embracing these techniques will undoubtedly elevate your printing projects to new heights.

Understanding DTF Printing Benefits

DTF printing has transformed the landscape of custom apparel and textile printing, offering unparalleled flexibility and efficiency. One of the primary benefits of DTF printing is its ability to deliver vibrant, full-color images directly onto a variety of fabrics without compromising on quality. This method allows for intricate designs and textures to be replicated flawlessly, making it ideal for businesses looking to provide unique and personalized products.

Another significant advantage of DTF printing is its cost-effectiveness, particularly for bulk printing. By utilizing a DTF gangsheet, users can maximize print space and minimize material waste, leading to higher profits and lower production costs. Additionally, the adhesive powder ensures that designs adhere effectively to fabrics, resulting in long-lasting prints that can withstand washing and wear.

Essential Materials for DTF Printing

To embark on your DTF printing journey, gathering the right materials is crucial. A high-quality DTF printer specifically designed for DTF inks is essential, as it ensures the best ink transfer onto the film. Coupled with premium DTF film, which acts as the medium for your designs, these materials form the backbone of successful DTF printing projects. Don’t overlook the importance of the adhesive powder, as it plays a vital role in binding the ink to the fabric during the heat transfer process.

In addition to the printer and film, a reliable heat press machine is necessary for executing the final transfer. This equipment applies the necessary heat and pressure to bond your prints to the fabric securely. Many users also find design software like Adobe Illustrator helpful for creating and optimizing their artwork before printing, making it easier to develop stunning designs for their DTF gangsheet.

Creating Your Design for DTF Printing

Creating an effective design for DTF printing involves strategic planning and creativity. Start with a clear vision of your artwork, ensuring it aligns with the capabilities of DTF printing. This includes using the correct color settings, like CMYK, to ensure your designs render accurately during the printing process. For gangsheet printing, consider arranging multiple designs efficiently on a single sheet, which maximizes your output and minimizes ink and film waste.

When designing, it’s paramount to account for the size and spacing of each design element. Test your layout before printing to prevent any misalignments or overlaps that could compromise the final product. By utilizing software tools effectively, you can bring your concepts to life while ensuring they are optimized for an exceptional visual impact once printed on fabric.

The DTF Printing Process Explained

The DTF printing process can seem complex but is rewarding once you break it down into manageable steps. Begin by adjusting your printer settings to match the specifications required for DTF inks, including resolution and film size. Once you print your designs onto the DTF film, it’s crucial to allow the ink to dry completely before moving onto the next step to avoid smudging, which can ruin your work.

After printing, the next step is applying the adhesive powder evenly over the still-wet ink. This technique ensures that the powder binds effectively with the ink when heated. Curing the adhesive is equally important, as this step solidifies the bond between the ink and the film, leading to durable prints. Subsequently, the design can be transferred to the fabric using a heat press, a step requiring precise temperature and timing to achieve the best results.

Troubleshooting Common DTF Printing Issues

Like any printing technique, DTF printing can present challenges that novice users might face. Common issues include misalignment of prints, incomplete ink transfer, or insufficient adhesion to fabrics. It’s important to conduct test prints before full-scale production to identify potential problems. Monitoring your print quality closely will help you catch issues early and adjust settings like temperature or pressure accordingly.

If you experience problems with adherence, make sure you’re applying the correct amount of adhesive powder and curing it adequately. Another tip is to keep your workspace clean and free of debris that could interfere with the printing process. By adopting a meticulous approach to troubleshooting, you can enhance the quality of your DTF prints and ensure more successful runs.

Exploring Creative Applications of DTF Printing

DTF printing opens up a world of creative possibilities across various industries. From custom apparel and sportswear to promotional items and personalized gifts, the applications are virtually limitless. Creators can experiment with unique fabrics, colors, and designs to produce products that resonate with their target audience. Utilizing DTF gangsheet printing allows for multiple designs to be printed simultaneously, which is a huge advantage for bulk orders.

Additionally, many artists and designers find DTF prints ideal for showcasing their artwork on clothing or home textiles. The ability to print high-resolution, detailed images makes it an attractive option for creatives looking to monetize their designs. By exploring different fabric combinations and printing techniques, businesses can carve out a niche market in the competitive world of custom prints.

Frequently Asked Questions

What is a DTF Gangsheet Builder Print?

A DTF Gangsheet Builder Print refers to a collection of multiple designs arranged on a single DTF film sheet, optimized for Direct-to-Film printing. This technique maximizes material efficiency by creating several prints at once, making it ideal for bulk production.

How do I create DTF prints using the Gangsheet Builder method?

To create DTF prints using the Gangsheet Builder method, first design your artwork in software like Adobe Illustrator. Arrange multiple designs on a single DTF film sheet, adjust your print settings accordingly, print the designs on the film, apply adhesive powder, and use a heat press to transfer the designs onto fabric.

What materials do I need for DTF Gangsheet Printing?

To successfully complete DTF Gangsheet Printing, you’ll need a DTF printer, DTF film, adhesive powder, a heat press machine, and design software such as CorelDRAW or Adobe Illustrator. These materials are essential for achieving high-quality prints.

What are common mistakes to avoid in DTF gangsheet printing?

Common mistakes in DTF gangsheet printing include incorrect printer settings, not allowing the ink to dry properly before applying adhesive powder, and using insufficient adhesive. Ensuring precise adjustments to your settings can help avoid these pitfalls and lead to successful prints.

Is there a beginner’s guide to DTF printing that includes gangsheet techniques?

Yes, many resources provide a beginner’s guide to DTF printing which covers gangsheet techniques. These guides typically include step-by-step instructions, tips for design creation, and troubleshooting advice to help beginners successfully create DTF prints.

What are the benefits of using DTF gangsheet printing for custom prints?

Using DTF gangsheet printing for custom prints offers benefits such as cost efficiency, as multiple designs can be printed simultaneously, and flexibility across various fabrics. This method also allows for vibrant, durable designs that can enhance your custom apparel offerings.

| Key Points | Details |

|---|---|

| Introduction | An overview of DTF printing and its accessibility for custom prints. |

| What is DTF Printing? | Direct-to-Film printing is a method for creating high-quality prints on different fabrics using specialized techniques. |

| Required Materials | DTF Printer, DTF Film, Adhesive Powder, Heat Press Machine, Design Software. |

| Step 1: Design Creation | Create designs in CMYK mode and arrange them for optimal use of the DTF film. |

| Step 2: Adjust Print Settings | Set appropriate ink type, resolution, and size on your printer. |

| Step 3: Print the Design | Print the design on DTF film and allow it to dry completely. |

| Step 4: Apply Adhesive Powder | Sprinkle adhesive powder over wet ink and heat cure to bind the ink. |

| Step 5: Transfer the Design | Place the printed DTF film onto the fabric and apply heat and pressure using a heat press. |

| Step 6: Cool Down and Peel | Allow to cool and then gently peel away the DTF film to reveal the design. |

| Tips for Success | Conduct test runs, maintain a clean workspace, and monitor print quality for optimal results. |

Summary

DTF Gangsheet Builder Print is revolutionizing the way custom prints are created, making this process easier and more efficient than ever. By following the step-by-step tutorial provided, you’ll be able to harness the power of DTF printing to produce stunning graphics on various fabrics. Start by gathering the right materials and utilizing the recommended techniques in design creation, printing, and transfer processes, ensuring your results meet high-quality standards. As you gain confidence, experiment with different designs to further enhance your custom printing skills. Happy printing to those embarking on this exciting journey!