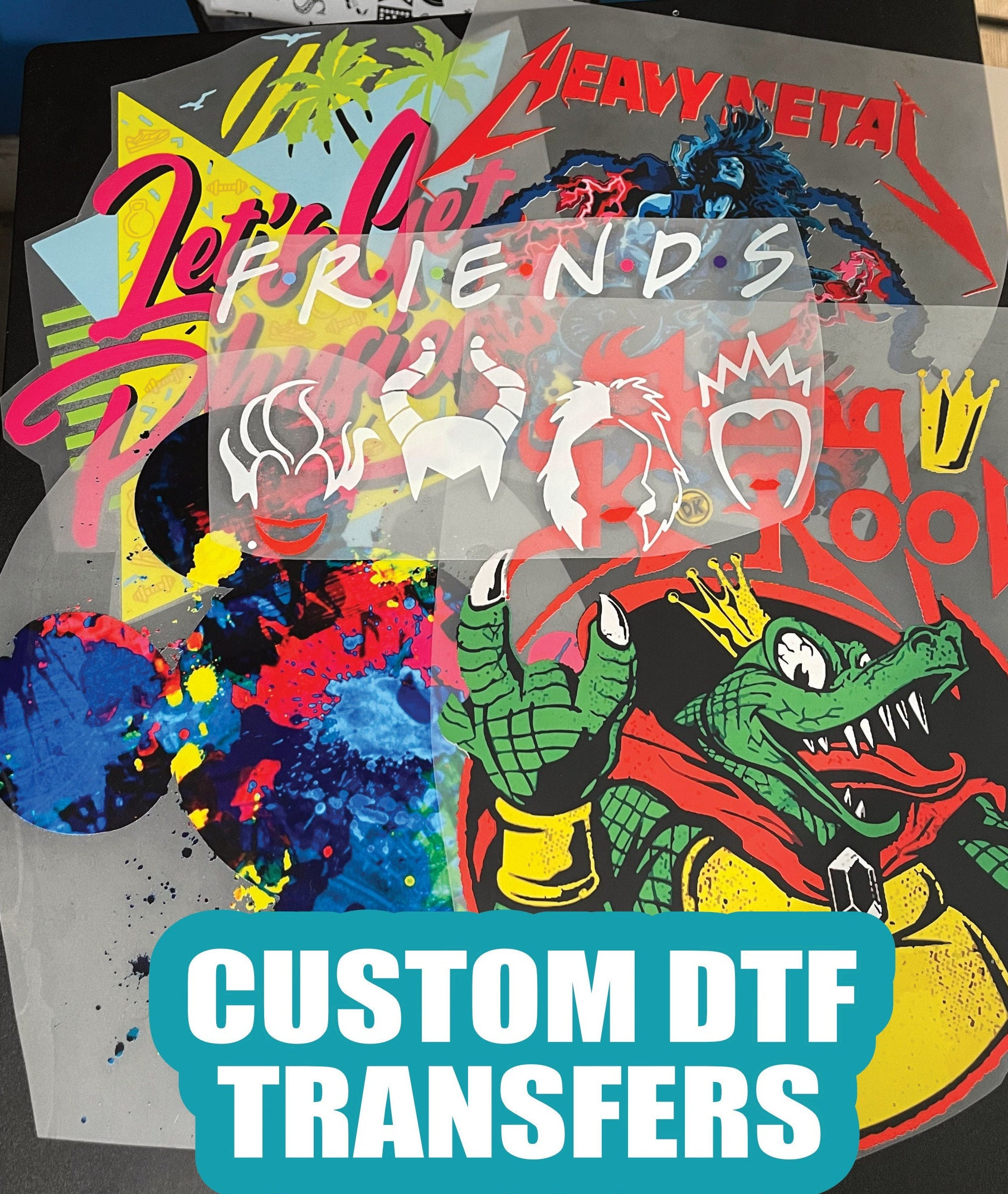

DTF transfers, or Direct-to-Film transfers, represent a groundbreaking advancement in fabric printing, empowering creators to achieve stunning colors and detailed designs with minimal effort. At the heart of this innovative process lies DTF printing, which requires a quality A3+ printer capable of delivering exceptional print accuracy. To ensure flawless results, a reliable heat press is essential for securing the transfer onto fabric. Complementing these tools, a DTF powder shaker enables an even application of adhesive powder, enhancing adhesion during the transfer process. Moreover, incorporating design placement tools into your workflow fosters precision, guaranteeing a polished finish that elevates your printing projects.

When exploring the world of fabric decoration, you may encounter terms like film transfers or direct-to-film technology, which encapsulate the essence of DTF transfers. This printing revolution utilizes specialized equipment like A3+ printers and heat presses to ensure vibrant results that stand out. A key component of this process is the careful application of adhesive powder, facilitated by a DTF powder shaker that maximizes efficiency. Additionally, design placement tools help achieve the meticulous alignment necessary for a professional finish. Embracing these advanced techniques not only enhances your creations but also propels your fabric printing endeavors to new heights.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is a modern technique that merges technology with art, allowing users to transfer vibrant designs directly onto fabric. This method is ideal for small and large scale production, opening up new avenues for both hobbyists and professionals. The ability to print on various materials, from cotton to polyester, unlocks creative potential, leading to unique products that cater to diverse customer preferences.

A thorough understanding of DTF printing involves not only the printing technique itself but also the crucial tools that enhance the process. From high-quality A3+ printers to effective heat press machines, the importance of each element cannot be underestimated. Gaining insights into the resources available will empower printers to produce superior results, reinforcing their position in a competitive market.

Frequently Asked Questions

What is DTF printing and how does it work?

Direct-to-Film (DTF) printing is a modern printing process that transfers vibrant designs directly onto fabric. It utilizes an A3+ printer to print designs onto a special film, followed by applying an adhesive powder using a DTF powder shaker. This process allows colors to remain bright and details to shine through, producing high-quality DTF transfers suitable for various fabric types.

What type of A3+ printer is best for DTF transfers?

For optimal DTF transfers, it’s crucial to use a high-quality A3+ printer specifically designed for DTF printing. Look for printers that support CMYK and white inks, as they ensure sharp details and accurate color reproduction. Brands known for performance and reliability in DTF applications will yield impressive results.

How does heat press usage impact DTF transfers?

Using a heat press is vital for successful DTF transfers, as it applies the necessary heat and pressure to bond the printed design with the fabric effectively. A good heat press should reach temperatures of 320°F to 350°F and offer adjustable pressure settings, ensuring durability and preventing issues like fading or peeling.

What role does a DTF powder shaker play in the transfer process?

A DTF powder shaker ensures an even application of adhesive powder onto the printed film, which is essential for the transfer to adhere properly during heat pressing. Proper usage of a powder shaker minimizes waste and contributes to achieving vibrant and long-lasting DTF transfers.

Why are Teflon sheets important for DTF transfers?

Teflon sheets are important when working with DTF transfers as they protect your designs from direct contact with the heat press, thereby preventing any sticking or damage. They also facilitate even heat distribution, which is critical for consistent results across multiple transfers.

How can design placement tools improve DTF transfer accuracy?

Design placement tools, such as measuring tapes and alignment grids, enhance the accuracy of DTF transfers by ensuring each design is positioned correctly on the fabric. This precision is crucial for achieving a professional look and avoiding misalignment, which can detract from the final product.

| Tool | Purpose | Key Features |

|---|---|---|

| High-Quality A3+ Printer | The foundation of successful DTF printing. | Compatible with CMYK inks, sharp and vivid prints. |

| Heat Press Machine | Applies even temperature and pressure for effective transfers. | Must reach 320°F to 350°F; adjustable pressure settings. |

| DTF Powder Shaker | Ensures an even application of adhesive powder. | Prevents wastage; essential for vibrant and durable prints. |

| Teflon Sheets and Silicone Protectors | Protects transfers and fabric during application. | Promotes even heat distribution; prevents scorching. |

| Design Placement Tools | Ensures accurate placement of transfers. | Includes measuring tapes, alignment grids, and heat-resistant tape. |

Summary

DTF transfers have transformed the fabric printing landscape, enabling creators to achieve vibrant, high-quality designs with relative ease. By utilizing the right tools including a high-quality A3+ printer, heat press machine, DTF powder shaker, Teflon sheets, and design placement tools, anyone can enhance their DTF printing process. This not only guarantees superior print quality but also streamlines production workflow, ensuring that every transfer is executed with precision. The investment in these essential tools can elevate your professional printing game, leading to more satisfying results and happier customers. Embracing DTF transfers is a strategic move for anyone looking to excel in the world of fabric printing.